This is a bit of a weird problem it seams, cause i'm having no luck with it.

When I print a cally box (calibration), the 'bottom' prints, then the walls print but they are a fraction to the left and backwards compared to the bottom. They then print nice and smooth till the 'top' of the box, where it goes back to the alignment used for the bottom of the box.

When printing a 'normal' print (which has variable amounts per layer) it is kinda all over the place by small amounts giving a much more rough edge.

Any idea what I should think about looking at or what might be wrong? I have looked at a number of things but haven't found anything amiss really..

Thicker layer offset

Moderator: CrazyIvan

Re: Thicker layer offset

sigh..

I've retighterned X and Y the belts and it didn't seem to make any difference. I've taken off the vibration feet and put them back on cause no difference. I've slowed down the print, and I've speed up the print.. no difference.. the top and bottom are still off set a small amount which is noticeable.

apart from the fact the top and bottom have plastic to extrude, I see no reason for this or anything.

I've just got no clue what's up..

I've retighterned X and Y the belts and it didn't seem to make any difference. I've taken off the vibration feet and put them back on cause no difference. I've slowed down the print, and I've speed up the print.. no difference.. the top and bottom are still off set a small amount which is noticeable.

apart from the fact the top and bottom have plastic to extrude, I see no reason for this or anything.

I've just got no clue what's up..

Re: Thicker layer offset

Sounds a bit odd. Layer shifting COULD be due to print temperature, where if the bottom layer sets cold before the next layer then layer 1+ could "drag" as it prints the higher layers.

Might not work but try setting a higher bed temperature, which should reduce the cooling during printing. And raise the nozzle temperature by 10-15 degrees, which will make the printed filament more fluid and less likely to drag.

If that helps then experiment with temperatures. However I have a funny feeling that it won't.

Might not work but try setting a higher bed temperature, which should reduce the cooling during printing. And raise the nozzle temperature by 10-15 degrees, which will make the printed filament more fluid and less likely to drag.

If that helps then experiment with temperatures. However I have a funny feeling that it won't.

Creality CR-10S owner posting as a private individual.

Re: Thicker layer offset

Thanks, I'll try raising the bed a bit.. or lowering it, I use a 30degree heated bed (oh, PLA printing by the way) and the nozzle temp around 180-200, I tried a bit of variation on it around that point without too much luck. problem is, how would it effect the top layer too?

for some reason, I just keep going back to 'when it prints 100% (base and top) it's one alignment, but when it prints less (15-20% infill for the main cube) it's a different alignment..

it's really hard to tell with non-uniform shapes but I wonder if I can whip up something with a few different 'layers' to try and figure this out...

for some reason, I just keep going back to 'when it prints 100% (base and top) it's one alignment, but when it prints less (15-20% infill for the main cube) it's a different alignment..

it's really hard to tell with non-uniform shapes but I wonder if I can whip up something with a few different 'layers' to try and figure this out...

Re: Thicker layer offset

Try bed temp of 70 degrees and nozzle 230 degrees - the latter is probably OTT for PLA so you will probably adjust it downwards after the trial. PLA at 230 might be too runny, you'll probably have stringing.

Bed temp of 70 is okay for PLA, though 60 is probably likely.

Your current temps are too low.

Bed temp of 70 is okay for PLA, though 60 is probably likely.

Your current temps are too low.

Creality CR-10S owner posting as a private individual.

Re: Thicker layer offset

really? mm.. normal okay.. but.. I'll try it ^_^ thanks.

might have to wait till tomorrow through.

might have to wait till tomorrow through.

Re: Thicker layer offset

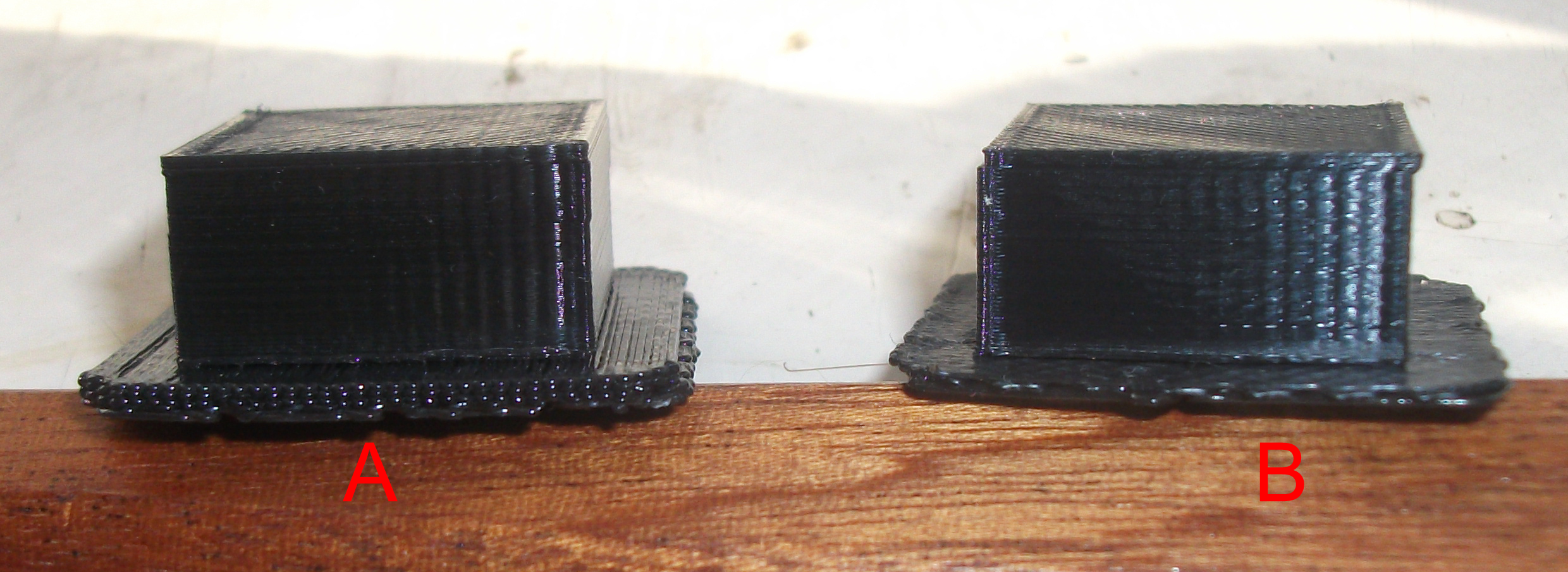

okay, probably a bit too big but i'm normally a pretty bad photographer and the details are probably important.

Cube A is the one I was able to just print off. 15% infill, 230degree Hotend, 60degree bed.

Cube B is one I printed before and pretty much like all the others of late. either 15% or 20% infill, 190degree hotend, 20degree bed.

You can't quite see the base on B, but you can clearly see where the top is at a different alignment, which my tests seam to say is the same as the base (but doesn't quite seem to be in this). Cube A looks much better.. but looks like an off-alignment a bit further down.. to tell the truth, i'm not quite sure if this is good or bad results..

also partly wondering if I need to see about a different cooling fan duct.. or tweak the one I got..

Re: Thicker layer offset

You might find that infill of 8% would be good for most prints. 15% and above is a bit too highand needed for parts which are subject to weight or stress.

Creality CR-10S owner posting as a private individual.

Re: Thicker layer offset

Looks like you might be over-extruding - you are squishing more filament than is necessary to fill a space, and this leaves blobs on the finishrf print.

Print a cube 20mm x 20mm x 20mm at 100% infill. If the cube is bloated you are over-extruding. If it is looking like it needs action from biafra (i.e. skinny and on hunger diet) then it is under-extruded, Ideally it will be a well shaped cube.. Your software will have a parameter defining extrusion, might need to be set to 90% or thereabouts.

Print a cube 20mm x 20mm x 20mm at 100% infill. If the cube is bloated you are over-extruding. If it is looking like it needs action from biafra (i.e. skinny and on hunger diet) then it is under-extruded, Ideally it will be a well shaped cube.. Your software will have a parameter defining extrusion, might need to be set to 90% or thereabouts.

Creality CR-10S owner posting as a private individual.

Re: Thicker layer offset

okay, i'll try a 100% infill print.

I don't think my software does.. I use Makerware (2.4.1.27). the newer Makerprint didn't seam to want to work (i'm reluctant to upgrade the firmware cause.. if it isn't broken, don't fix it kinda thing ^_^)

I do also have ReplicatorG but I don't use it and Cura (15.04.4).. I think I tried Cura cause a friend recommended it but it didn't want to work with my printer, but i'll have to try it again sometime..

for now, i'll print a 100% infill cube and see what happens.. take about an hour.

I don't think my software does.. I use Makerware (2.4.1.27). the newer Makerprint didn't seam to want to work (i'm reluctant to upgrade the firmware cause.. if it isn't broken, don't fix it kinda thing ^_^)

I do also have ReplicatorG but I don't use it and Cura (15.04.4).. I think I tried Cura cause a friend recommended it but it didn't want to work with my printer, but i'll have to try it again sometime..

for now, i'll print a 100% infill cube and see what happens.. take about an hour.