I had long suspected there was something not right with my Tina2S's bed heater. It was not reaching the set temperature at times, and watching the temp on the info screen showed it sometimes going up, sometimes down. I was putting up with that while I still got good prints, but then I had a 4+ hour print I left running overnight ruined by warping and I couldn't tolerate it any longer.

The most likely fault was a broken wire to the heater itself – the sensor was still giving sensible readings. Flexing the cable by hand confirmed that suspicion, the fan changed pitch as the PSU got loaded intermittently.

(Some of the photographs below are cribbed from

this post, as I did not keep a photo-journal of this repair.)

- Tina2Anatomy-23-small.jpg (246.24 KiB) Viewed 19 times

The wires concerned are within the mesh sheath on the right of the print bed, which passes through the cable duct behind the front right corner of the Tina2S's outer case. It emerges from the duct just below the controller board, and plugs into the controller board with a large 2-pin connector for the power, and a small 2-pin for the sensor. With the printer turned onto its right side, the connectors can be seen (just!), identified, and disconnected: the power plug is obvious with thick red and black wires, the sensor plug is adjacent to it with thin white wires.

IMPORTANT: Tie the end of a couple of feet of string to the power plug before proceeding further. The string will make re-assembly much easier.

While the printer is on its side, release the Y belt from the carriage anchor.

Stand the printer upright again. Now proceed to disassemble the print plate from the Y bearings by removing the 8 screws into the bearing blocks (NOT the two screws securing the belt anchor in the centre of the plate)...

- Tina2Anatomy-24-small.jpg (241.95 KiB) Viewed 19 times

...and withdraw the cable. Untie the string from the plug, leaving the string in place through the duct.

- Tina2Anatomy-25-small.jpg (239.45 KiB) Viewed 19 times

Fixed by admin.

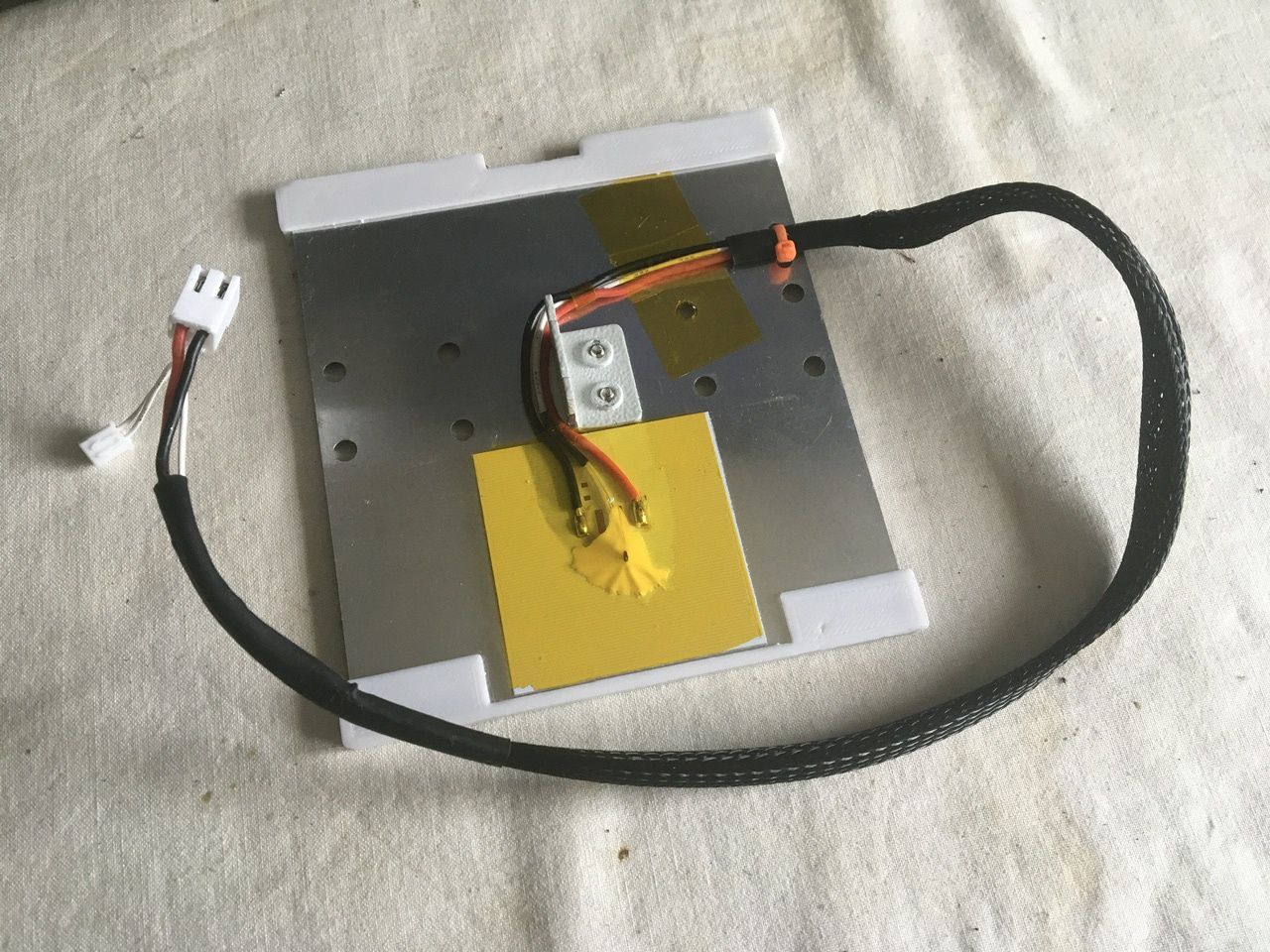

NB: the above is a photo of my

repaired assembly, not the original one. It also shows my magnetic plate locating fences (the white pieces at opposite ends of the plate) for

fine-tuning Y capability.

Be aware of the following:

- The transparent yellow tape over the heater and securing the cable near the zip tie is high-temperature tape.

- The sheath will fray at the ends when the heat-shrink tubing is removed.

- New heat-shrink tubing won't fit over the plugs.

- The solder joints connecting the power wires to the heater pad are on a huge heat sink, so are all but impossible to unsolder/re-solder (and I didn't want to risk heat damage by cooking the whole lot).

In the event, I found not just one fractured wire but both, with blackening around the break (inside the insulation) very similar to the

nozzle heater repair I did previously. The location was where the cable bends back on itself, as seen in the top photo. That point is where the cable flexes repeatedly as the carriage moves in Y, and is necessary to allow the freedom of movement.

The break was obvious: while the rest of the wire was relatively stiff, it was floppy at that point and parted easily when pulled (don't do this yet, see instructions below).

The following is not the exact sequence of operations I used, but that's where you can benefit from my experience of doing this for the first time. These are not proven instructions, particularly details like the pre-shrunk ODs (outside diameters) of heat-shrink tubing. Any feedback welcome.

Before you start, you will need:

- Replacement wire. It does not matter what colour it is, but red and black wire would be nice. Only need a foot of each, if that (or a couple of feet of one colour). The original wire is 1.75mm OD 16-strand 0.2mm (0.5mm²), so choose something similar (no thinner) and as flexible as possible. It doesn't matter how thick the OD is (within reason), unless you've tuned (or are going to tune) the printer's Y capability as per this thread. Wires taken from a length of 0.5mm² (3A) mains flex will do.

- Heat-shrink sleeving, fine (pre-shrunk OD 3mm) and medium (OD 10mm).

- Small zip tie.

- Sticky tape, eg electricians' PVC insulating tape (specification unimportant).

- Soldering iron and solder, miscellaneous tools. Note that leaded solder is much easier to work with than lead-free solder!

As previously noted, it would be a pig to replace the wire at the solder connections to the heater, so don't try. Similarly the crimped connection at the connector, so don't. Instead, splice in a length of wire to replace just the section that is broken, with the joints in places which do not suffer flexure.

- Carefully peel back the high-temperature tape securing the wires to the plate, sufficient to release the wires. Do this from the front edge of the plate – where the tape passes across a mounting hole it will be more fragile.

- Cut the zip tie.

- With a sharp craft knife, slit the sleeving at the end of the mesh sleeve (just this end, not the other end) and remove it.

- Trying not to let the mesh fray any more than it is already, pull it back to bare the wires as far as possible and temporarily tape it in place (helping to prevent fraying and clearing the working area). Identify the location of the break.

- On one wire only: Cut the wire as far up the cable as is comfortable to work with. Strip the top end of the cut wire about ¼". Strip the end of the replacement wire similarly, and solder them together (I like to "merge" the stranded conductors into each other, and they then need taping to a wood block – or something – to solder them... or two pairs of hands). Feed on a 1" length of 3mm heat-shrink to insulate the joint (ideally use a heat gun to shrink it, although a soldering iron will do it). Feed another 1" length of heat-shrink onto the same wire, for later.

- Cut the same wire at the plate, next to the belt anchor. Now stretch the cable out straight, right through from the connectors to the heater, so the remaining intact wire is taught. Cut the replacement wire so there is a ¼" overlap with the cut end to the heater.

- Now you can cut the other wire next to the heater, at the same position as the first.

- Repeat step 5 for the other wire.

- Cut the replacement wire to the same length as the first.

- Feed a 1½" length of 10mm heat-shrink over both wires together.

- Strip the ends and solder, make sure the heat-shrink is as far away from the soldering as possible.

- Slide the 3mm heat-shrink down to cover the joints, and shrink. Slide the 10mm down to cover both joints, and shrink.

- Remove the crimp terminals from the power connector. This can be done using a fine screwdriver to depress the metal latches, and then the terminal slides out of the housing easily.

- Feed the sensor plug through a 1½" length of 10mm heat-shrink, then the power crimps. Slide the heat-shrink over the top end of the mesh sheath, then remove the tape securing the bottom end. Stretch the sheath down over the repair to the edge of the plate, and slide the heat-shrink down to just cover the end of the sheath. Shrink the tube to secure everything.

- Check the correct orientation from the photos, and re-fit the crimp terminals into the connector housing (it probably doesn't actually matter which way around they are, but...). If the latches don't hold, having depressed them it may be necessary to tease them out again so they latch properly.

- Secure the cable to the plate with a zip tie, as per photos. If you have tuned your Y motion, take care to ensure the tie (and the thickness of the cable at that point) won't foul the chassis.

- Replace the high-temperature tape.

To re-assemble the printer, tie the string added previously to the power plug, and use it to tease the cable through the cable duct. Plug in the connectors (fiddly!).

Assemble the bearing blocks, position the print plate over them, and refit the screws. Under the printer, re-secure the Y belt to the anchor.

Check the plate moves freely to both ends in Y. It should reach the back end-stop (the microswitch should click) before the bed heater cable fouls the Z motor coupling. At the front end-of-travel, f the Y tuning has been performed, the cable under the build plate should clear the lip of the chassis.

If the Y motion can't trigger the end-stop microswitch, the printer will report a Y error when it tries to home the nozzle.

NB: With the disassembly required to repair the bed heater cable, it would be an excellent opportunity to perform some of the Y tuning modifications at the same time –

see HERE.